PLANNING

Creating detailed technical drawings. These drawings contain all the necessary

information for manufacturing, including precise dimensions, material specifications, tolerances, and

assembly instructions

POPULAR QUESTIONS

When planning a metal fabrication project, various

questions need to be addressed to ensure a suc and efficient execution.

Design and technical specifications for a fabrication project can vary significantly depending

on factors such as the type of welding process, materials being welded, and the intended

application of the welded components. However, here are some general considerations and

specifications

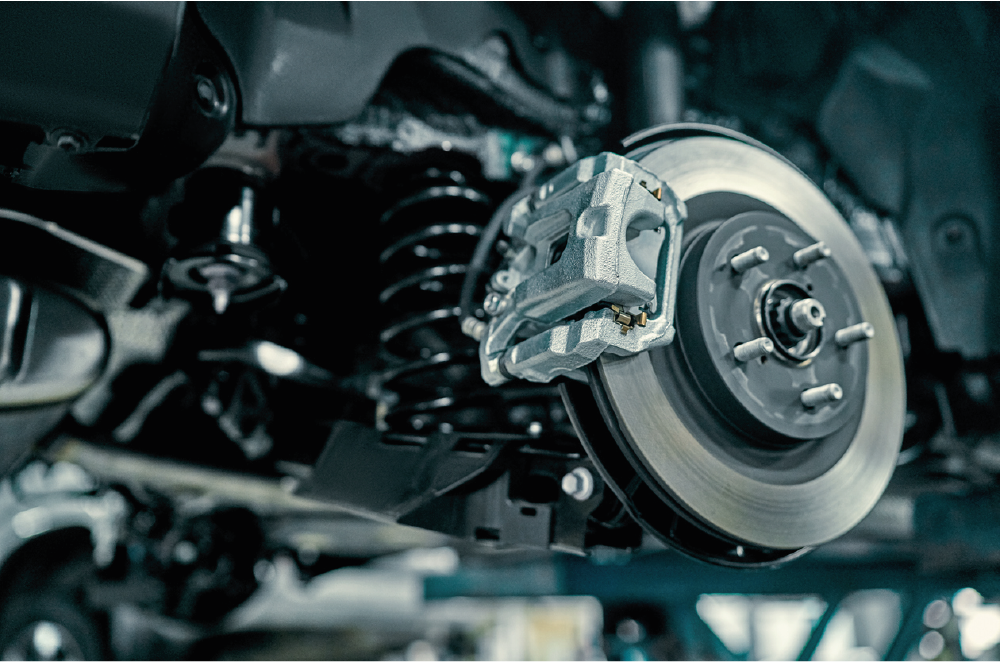

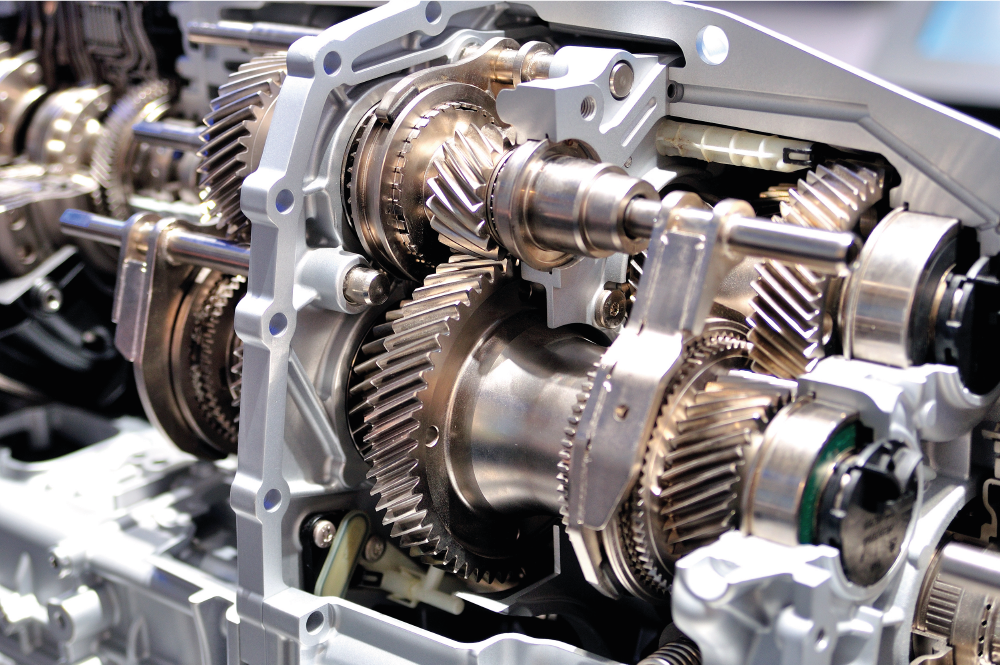

For a mechanic project will depend on the specific task or repair being undertaken.

Can vary depending on factors such as the scope of work, complexity of the task, availability of

resources, and external factors like parts delivery.

For a fabrication or car repair can vary depending on factors such as the scope of work,

complexity of the task, required materials, labor costs, and overhead expenses.

FABRICATION

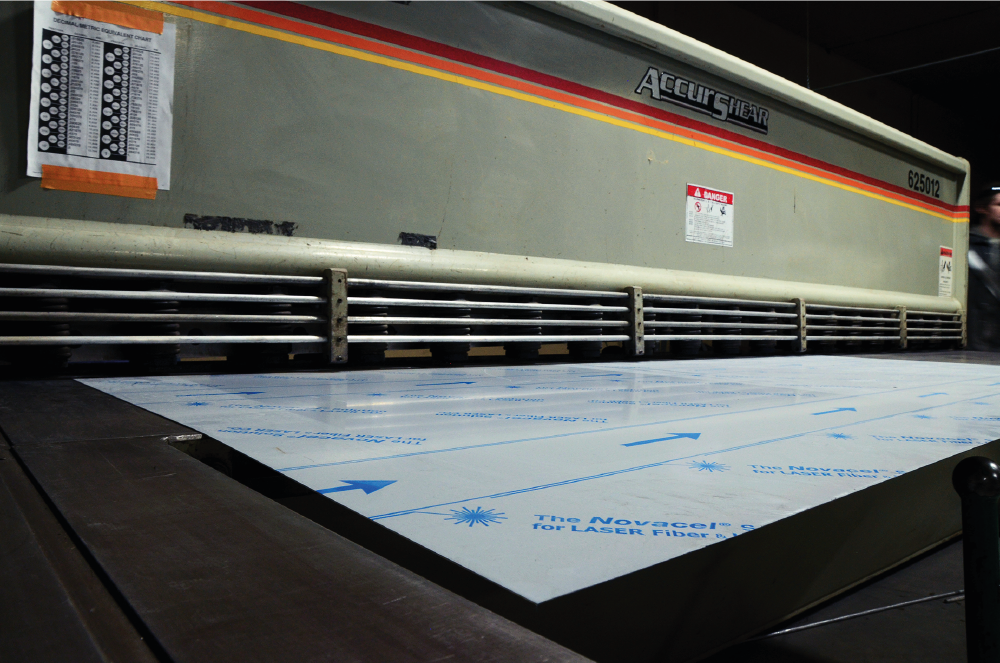

Cutting:

The chosen metal is cut into the required shapes and sizes using various techniques.

Common

cutting methods include laser cutting, plasma cutting, waterjet cutting, and traditional methods like

sawing or shearing.

Forming:

Bending and Shaping: Metal sheets or pieces may need to be bent or shaped to achieve the desired form.

This

is often done using press brakes, rollers, or other forming equipment.

POPULAR QUESTIONS

When planning a metal fabrication project, various

questions need to be addressed to ensure a suc and efficient execution.

Design and technical specifications for a fabrication project can vary significantly depending

on factors such as the type of welding process, materials being welded, and the intended

application of the welded components. However, here are some general considerations and

specifications

For a mechanic project will depend on the specific task or repair being undertaken.

Can vary depending on factors such as the scope of work, complexity of the task, availability of

resources, and external factors like parts delivery.

For a fabrication or car repair can vary depending on factors such as the scope of work,

complexity of the task, required materials, labor costs, and overhead expenses.

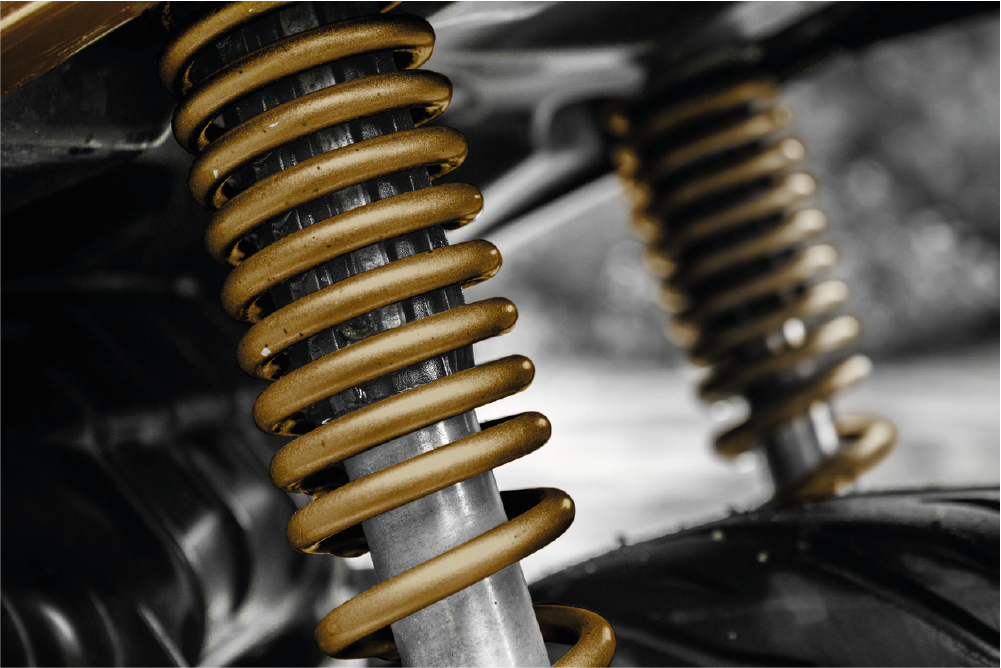

WELDING

we offer a service in accordance with the most stringent national and international

quality standards,

and has the execution of its welding procedures with qualified welders and certified supervisory personnel

with extensive experience in the different branches of the industry.

POPULAR QUESTIONS

When planning a metal fabrication project, various

questions need to be addressed to ensure a suc and efficient execution.

Design and technical specifications for a fabrication project can vary significantly depending

on factors such as the type of welding process, materials being welded, and the intended

application of the welded components. However, here are some general considerations and

specifications

For a mechanic project will depend on the specific task or repair being undertaken.

Can vary depending on factors such as the scope of work, complexity of the task, availability of

resources, and external factors like parts delivery.

For a fabrication or car repair can vary depending on factors such as the scope of work,

complexity of the task, required materials, labor costs, and overhead expenses.

FINISHING

"finishing" refers to the process of applying various treatments and techniques to a

metal workpiece

to enhance its appearance, durability, and functionality. The finishing step comes after the primary

fabrication processes, such as cutting, welding, and forming, have been completed. The goal

of finishing is to improve the overall quality of the metal product and meet specific requirements or

standards. There are several common finishing techniques in metal fabrication, including:

Surface Cleaning

Removing any residues, such as oils, grease, or scale, from the metal surface through processes

like degreasing or sandblasting.

Grinding and Polishing

Smoothing the surface of the metal through grinding and polishing to achieve a uniform and aesthetically

pleasing appearance.

POPULAR QUESTIONS

When planning a metal fabrication project, various

questions need to be addressed to ensure a suc and efficient execution.

Design and technical specifications for a fabrication project can vary significantly depending

on factors such as the type of welding process, materials being welded, and the intended

application of the welded components. However, here are some general considerations and

specifications

For a mechanic project will depend on the specific task or repair being undertaken.

Can vary depending on factors such as the scope of work, complexity of the task, availability of

resources, and external factors like parts delivery.

For a fabrication or car repair can vary depending on factors such as the scope of work,

complexity of the task, required materials, labor costs, and overhead expenses.

PAINTING

Painting is a common finishing method in metal fabrication that involves applying a

layer of paint to the surface

of a metal workpiece. The primary purposes of painting in metal fabrication include enhancing the

appearance,

providing corrosion resistance, and offering additional protection against environmental factors.

POPULAR QUESTIONS

When planning a metal fabrication project, various

questions need to be addressed to ensure a suc and efficient execution.

Design and technical specifications for a fabrication project can vary significantly depending

on factors such as the type of welding process, materials being welded, and the intended

application of the welded components. However, here are some general considerations and

specifications

For a mechanic project will depend on the specific task or repair being undertaken.

Can vary depending on factors such as the scope of work, complexity of the task, availability of

resources, and external factors like parts delivery.

For a fabrication or car repair can vary depending on factors such as the scope of work,

complexity of the task, required materials, labor costs, and overhead expenses.

UNRIVALED EXPERTICE

UNRIVALED EXPERTICE TAILORED SOLUTIONS

TAILORED SOLUTIONS QUALITY MATERIALS

QUALITY MATERIALS RELIABLE EXECUTION

RELIABLE EXECUTION COMPETITIVE PRICING

COMPETITIVE PRICING